Under the background of global advocacy of energy conservation, emission reduction and sustainable development, the dump truck industry is facing an urgent need to transform towards green and efficient. Traditional fuel dump trucks have many problems such as high energy consumption, serious emission pollution and high maintenance costs, which are difficult to meet the dual demands of current environmental protection regulations and corporate cost reduction and efficiency improvement. With its significant energy-saving advantages, zero tail gas emission characteristics and excellent power performance, the electric drive system has become the core technical path for the dump truck industry to achieve transformation and upgrading. In-depth exploration and extensive application of dump truck electric drive system solutions are not only of key significance to reducing energy consumption and reducing environmental pollution, but will also effectively promote the dump truck industry to move forward in the direction of intelligence and electrification, injecting strong impetus into the sustainable development of the industry.

System architecture and principles

1 Overall architecture

The electric drive system of a dump truck mainly covers four core parts: power system, electric transmission system, auxiliary system and vehicle control system. As the source of energy, the power system provides electric energy for the operation of the vehicle; the electric transmission system is responsible for accurately converting electric energy into mechanical energy to drive the vehicle; the auxiliary system ensures the normal operation of various auxiliary equipment of the vehicle; the vehicle control system is like the “brain” of the vehicle, which coordinates and intelligently controls various subsystems to ensure efficient and stable operation of the vehicle.

2 Power system

Power battery: Lithium iron phosphate battery is usually selected because of its outstanding advantages such as high energy density, long cycle life, excellent safety and good thermal stability. For example, the lithium iron phosphate battery pack equipped with a certain dump truck has an energy density of up to 180Wh/kg, a cycle life of more than 3,000 times, and can work stably in a wide temperature range of -20℃ to 55℃. Through a reasonable battery management system (BMS), the battery charging and discharging process can be closely monitored and accurately controlled to effectively prevent abnormal conditions such as overcharging, over-discharging and overheating, greatly extending the battery life.

Charging system: supports multiple charging methods to meet the needs of different scenarios. AC charging is suitable for long-term charging scenarios such as night parking, and the charging power is generally between 7kW and 22kW; DC fast charging can replenish a large amount of power for the vehicle in a short time, and the charging power can reach 120kW or even higher. Some advanced dump trucks are also equipped with wireless charging technology. By laying wireless charging equipment in specific areas, the vehicle can be automatically charged without plugging and unplugging the charging cable, which significantly improves the convenience of charging.

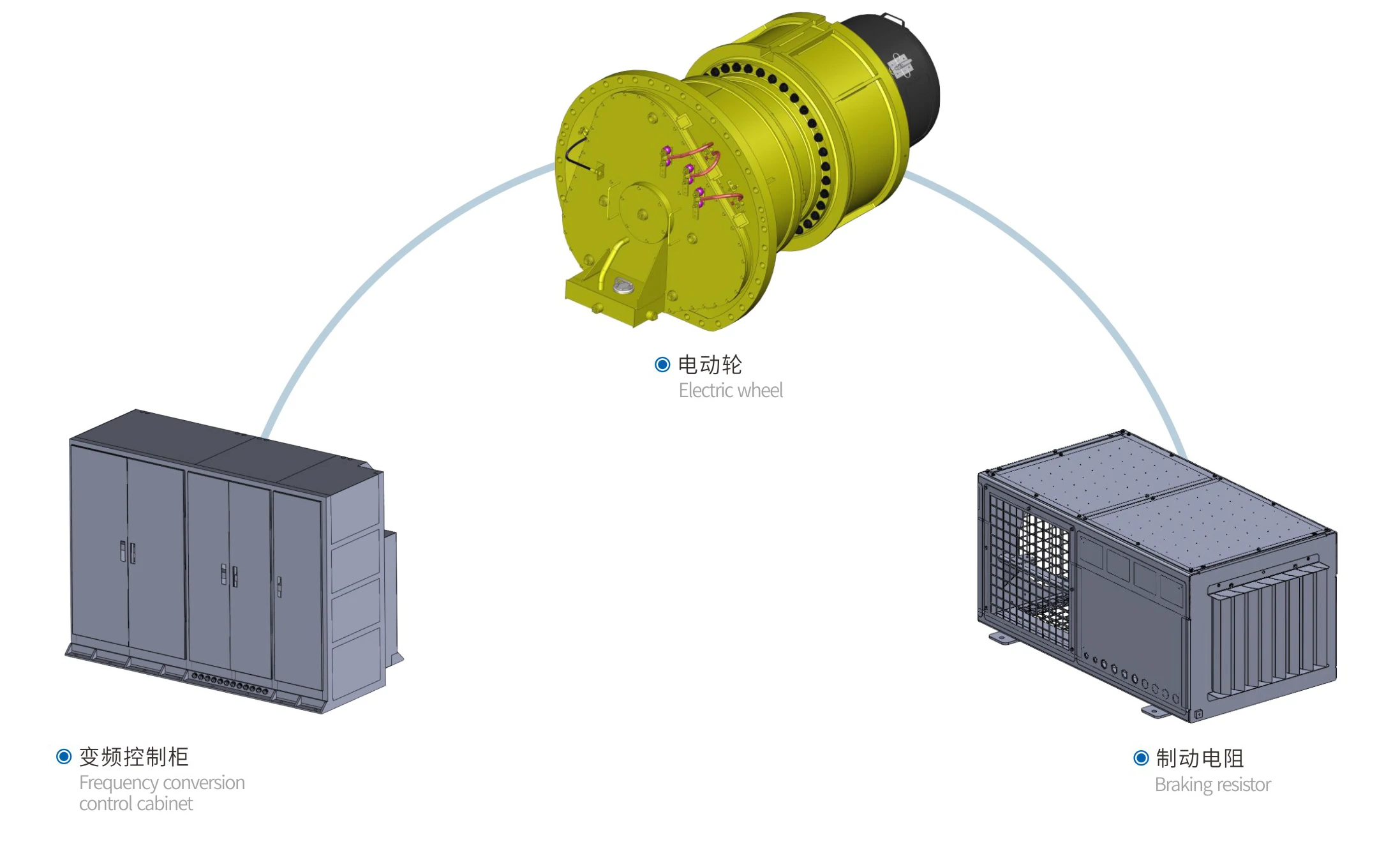

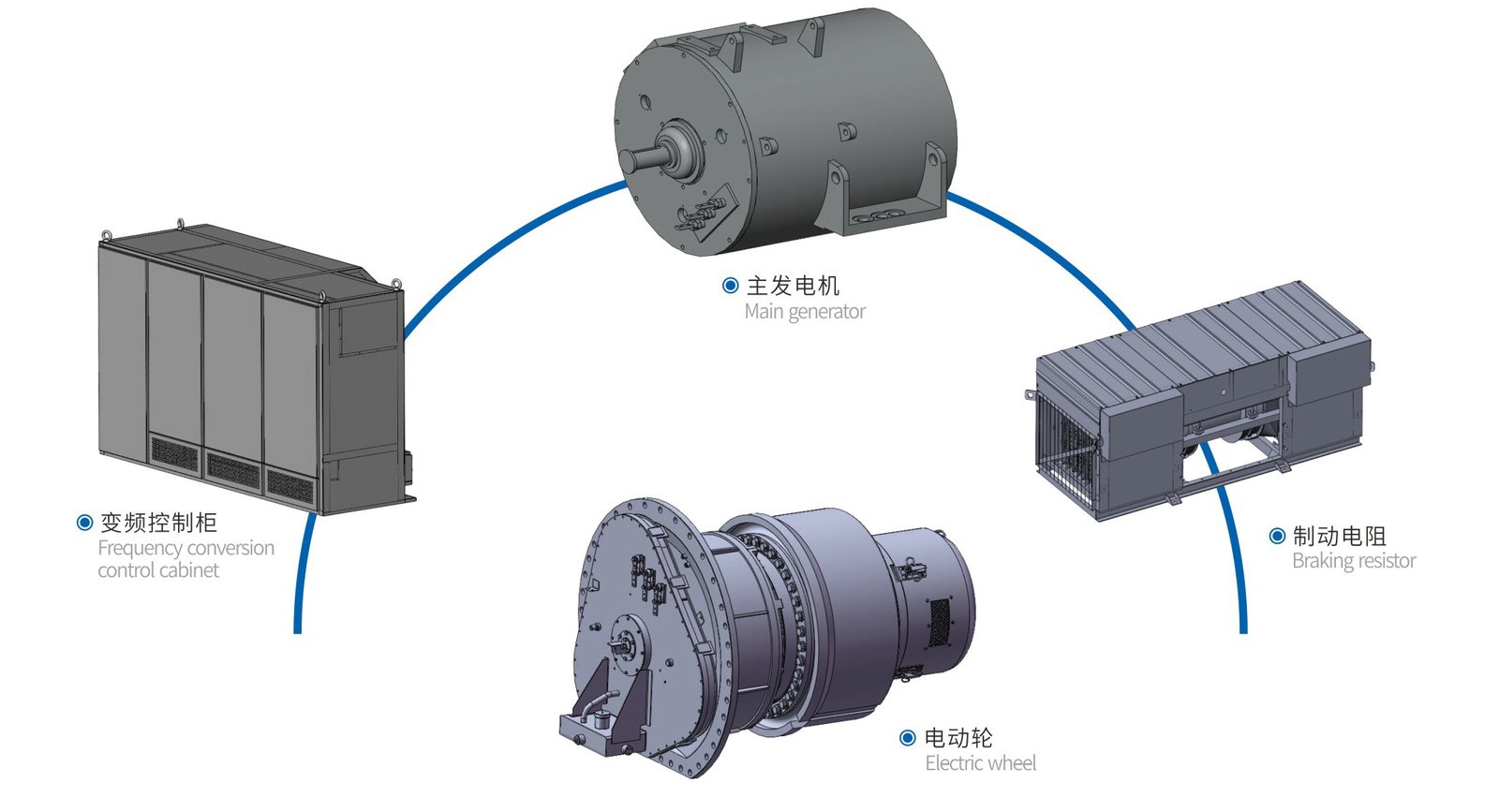

3 Electric drive system

Motor and controller: Traction motors mostly use permanent magnet synchronous motors, which have the advantages of high power density, high efficiency, wide speed regulation range and precise torque control. The matching motor controller uses advanced vector control algorithms to accurately adjust the motor speed, torque and steering according to the instructions issued by the vehicle control system.

Transmission: Common transmission methods include direct drive and reduction drive. The direct drive mode has a simple structure and high transmission efficiency. It is suitable for working conditions with high requirements for spatial layout and relatively stable loads. The deceleration drive achieves torque amplification through the reducer, enhances the vehicle’s climbing ability and acceleration performance, and is more widely used in heavy-duty dump trucks.

4 Auxiliary system

Steering assistance: The electric power steering (EPS) system is used to accurately provide assistance according to the vehicle speed and the driver’s steering operation force, making the steering operation lighter and more flexible. At the same time, the EPS system can also work with the vehicle control system to achieve advanced functions such as automatic return and lane keeping assistance. For example, when the vehicle speed is low, the EPS system provides greater assistance to facilitate the vehicle to turn in a narrow space; when the vehicle speed is high, the assistance gradually decreases to ensure the stability of the vehicle.

Braking assistance: Electric braking and mechanical braking work together to build an efficient and reliable braking system. During the vehicle deceleration process, the electric brake converts the motor into a generator state, converts the vehicle’s kinetic energy into electrical energy and feeds it back to the battery, realizing energy recovery and effectively reducing energy consumption. Mechanical braking is used as a backup braking method to ensure that the vehicle can brake and stop quickly in an emergency. For example, when a vehicle is driving on a long downhill section, electric braking can take on most of the braking tasks, stabilize the vehicle speed within a safe range, and recover electrical energy at the same time; when the electric braking fails or the braking force is insufficient, the mechanical braking immediately intervenes to ensure driving safety.

Other auxiliary equipment: including air conditioning, lighting, on-board electronic equipment, etc., are all powered by the power system. Through the intelligent control system, the energy consumption of these auxiliary equipment can be optimized and managed, and energy consumption can be minimized while meeting the normal use needs of the vehicle. For example, the intelligent air conditioning control system is used to automatically adjust the cooling or heating power of the air conditioner according to the temperature and humidity in the car; LED lighting technology is used to reduce lighting energy consumption while ensuring lighting brightness.