Xiangdian Heavy Equipment Co., Ltd. was formally established in September 2007. It is controlled by Xiangdian Group Co., Ltd. and jointly established by ten units and natural persons including Xiangtan Electric Co., Ltd. and China Power Investment Huolinhe Coal and Electricity Group Co., Ltd. Its predecessor was the Vehicle Division of Xiangtan Electric Co., Ltd. Since its establishment, it has focused on the research and development, production and sales of heavy electric transmission vehicles for mining, explosion-proof battery mining electric locomotives, overhead wire mining electric locomotives, rail transit vehicles and special equipment vehicles. The company is located in a superior geographical location, on the bank of Xiangjiang River in Xiangtan City. The surrounding transportation network is extremely developed. It is surrounded by the Beijing-Zhuhai Expressway, Shangrui Expressway, Beijing-Guangzhou Railway, Hunan-Guizhou Railway, and Wuhan-Guangzhou Special Railway. It is only 60 kilometers away from Changsha Huanghua International Airport. The railway line goes directly to the factory, which provides great convenience for the transportation of raw materials and the distribution of products.

As a pioneer in the field of mining transportation vehicle manufacturing in my country, Xiangdian Heavy Equipment has achieved fruitful development. As early as the 1950s, its predecessor had already devoted itself to the development of electric vehicles for mining transportation, and in 1977, it successfully developed China’s first 108t electric wheel dump truck, breaking the foreign technology monopoly in this field at that time and laying a solid foundation for the localization of mining transportation equipment in my country. After years of technical precipitation and market tempering, the company has now formed a complete product system, covering a full range of 108t-330t mining electric wheel dump trucks, as well as mining locomotive products of various tonnages such as 2.5t-45t. The products are not only sold well in major domestic open-pit mines and large-scale water conservancy engineering construction projects, but also exported to overseas markets such as Europe, South America, and Southeast Asia. A total of more than 1,000 vehicles of various types have been manufactured, establishing a good brand image in the domestic and foreign markets.

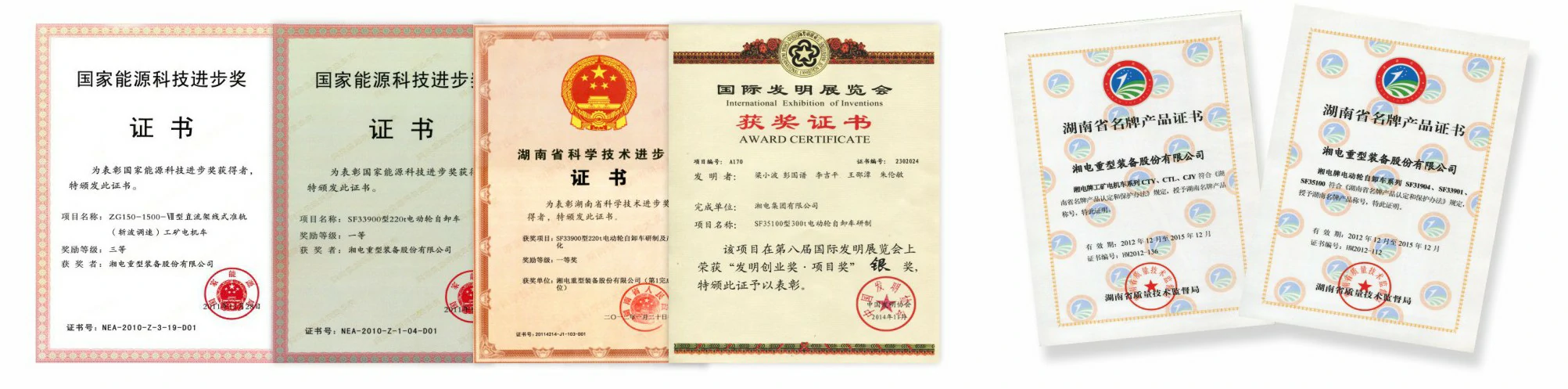

Technological innovation has always been the core driving force for the development of Xiangdian Heavy Equipment. The company attaches great importance to R&D investment, has a high-quality R&D team composed of senior experts and technical backbones in the industry, and has built a complete R&D innovation system. It has 5 national and 3 provincial technology innovation R&D platforms, including the National Recognized Enterprise Technology Center and the National Key Laboratory of Offshore Wind Power Technology and Testing. With strong R&D capabilities, the company has continuously overcome key technical problems in the industry and achieved a series of breakthrough results. At present, the company has 454 valid patents, including 108 invention patents and 154 product patents. It has successively undertaken more than 30 “863 Plan”, “973 Plan” and national science and technology support projects, and national defense key engineering projects. It has presided over and participated in the formulation (revision) of 83 national industry standards, and maintained a leading position in technology in the domestic mining transportation vehicle manufacturing industry.

Under the current global background of advocating green and low-carbon development, Xiangdian Heavy Equipment actively responds to the national “dual carbon” strategy and vigorously promotes the research and development and production of green mining equipment. The world’s first 120-ton and 200-ton pure electric mining electric wheel dump trucks independently developed by the company have been successfully launched and put into market application, causing a sensation in the industry. These pure electric dump trucks use advanced power battery drive technology, integrate efficient pure electric power systems, precise energy management systems and advanced AC transmission systems, and have completely independent intellectual property rights. Taking the 200-ton pure electric mining electric wheel dump truck as an example, its battery capacity exceeds 2900kWh, and the world’s first 3MW DC fast charging technology is used to achieve an efficient operation mode of charging for 1 hour and running at full load for 8 hours. According to actual calculations, a single vehicle can reduce carbon dioxide emissions for mines by more than 1,500 tons per year, while helping mines save more than 40% of operating costs, providing strong technical support and product guarantees for the green transformation of the mining transportation industry.