1 Analysis of electric drive configurations for new energy commercial vehicles

The central electric drive configuration of new energy commercial vehicles has high passability and is suitable for engineering scenarios with harsh working conditions; the efficiency and integration advantages of the integrated electric drive axle can be fully applied to tractors, especially large-battery models; the distributed medium- and short-term commercialization potential is low.

1.1 Central electric drive

A transmission is added to the direct drive motor to increase the starting slope or reduce the motor torque requirement to reduce costs.

Advantages:

① All-condition adaptability: Excellent climbing performance and power performance, adaptable to all operating scenarios;

② Minimal changes to the vehicle platform: The layout is largely the same as that of traditional fuel-powered vehicles, reducing technical development complexity.

Disadvantages:

① The longitudinal drive shaft and axle spiral bevel gears result in low power transmission efficiency;

② The design is not compact, requiring a large layout space, which also occupies space for the power battery.

Applicable scenarios: Heavy-load scenarios in non-paved road projects with large climbing gradients, harsh working conditions, and special requirements for passability.

1.2 Integrated Electric Drive Axle

The electric motor and transmission are directly integrated into the axle.

Advantages:

① High integration: Compact structure and minimal footprint leave more space for the power battery;

② Eliminates efficiency losses in the drive shaft and spiral bevel gears, resulting in high transmission efficiency, a shorter drive chain, and enhanced brake energy recovery.

Disadvantages:

① Increased unsprung mass: The motor and reducer integrated into the axle affect comfort and handling;

② Limited maneuverability: Reduced rear axle ground clearance makes it unsuitable for harsh conditions such as construction.

Applicable scenarios: Compared with central drive, the efficiency and space integration are comprehensively improved, and it is suitable for highway transport tractors such as long-distance trunk line efficient logistics.

1.3 Distributed Electric Drive

The integrated electric motor and transmission are installed next to or inside each wheel.

Advantages:

① High transmission efficiency: The drive path from the motor to the wheels is shorter, minimizing transmission efficiency losses.

② Compact structure: Minimum size and weight, maximizing space for the power battery and meeting the requirements of low-floor buses.

③ Enables optimal torque control.

Disadvantages:

① Difficulty overcoming technical bottlenecks: The vehicle platform requires significant changes, resulting in high technical difficulty; the need for two motors and a matching K-shifter increases cost and technical complexity; electronic differential control is challenging, requiring stringent functional safety requirements;

② Increased unsprung mass: This impacts handling and comfort, and the motors bear significant road impact loads.

Applicable scenarios: Due to the extremely high technical development difficulty, cost and application reliability, large-scale commercial application is still premature.

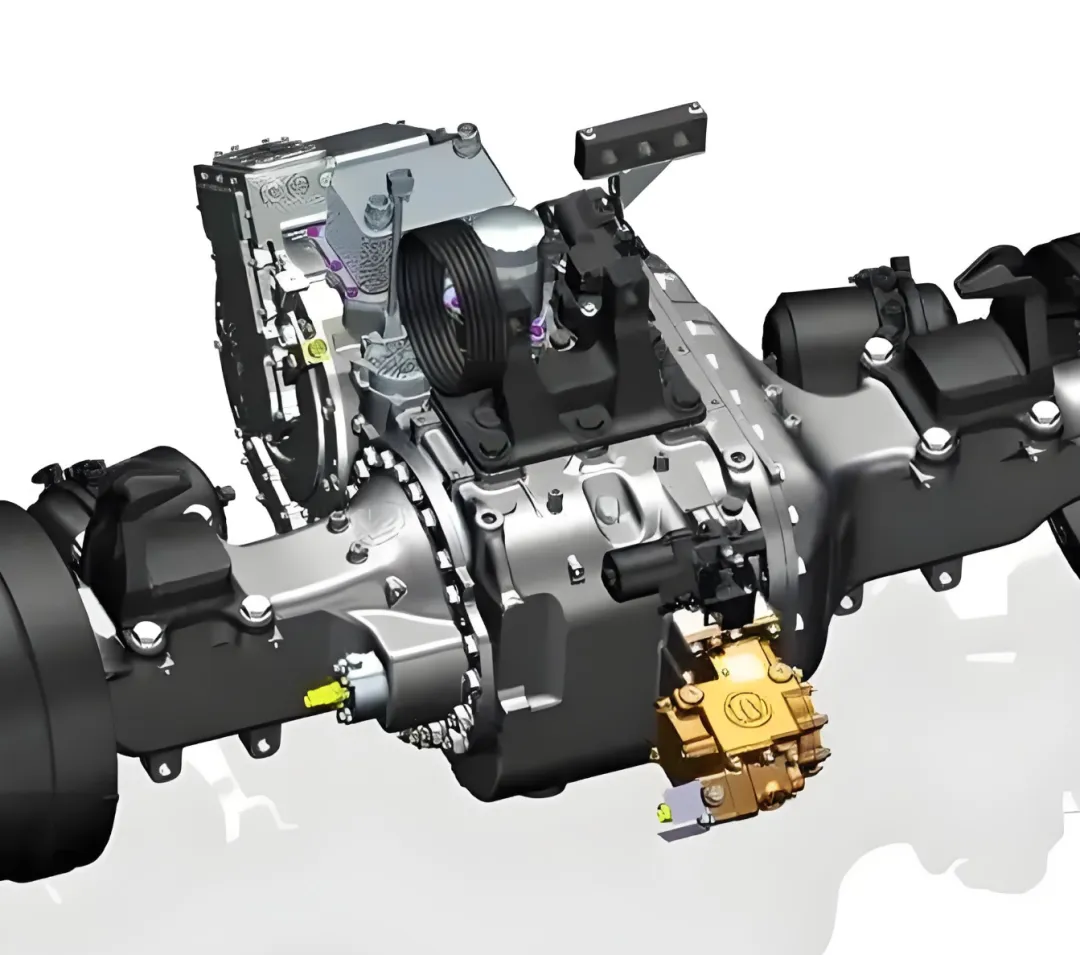

2 New energy commercial vehicle central electric drive

2.1 Single and Dual Motor Selection for Central Drive Technology Configuration

There are two main configurations: “single motor + eAMT” and “dual motor + eAMT”:

① Single motor + eAMT: The mainstream pure electric heavy-duty truck configuration features a single motor with low speed and high torque (3500rpm/3000Nm) and a four-speed automatic transmission.

② Dual motor + eAMT: The main configuration features dual motors with a multi-speed transmission (eDMT). The motors can be either primary or auxiliary, with configurations of 2, 3, or 4 gears. Alternatively, dual motors with the same high speed and low torque (11000rpm/750Nm) can be used to achieve uninterrupted power, a trend that will be the mainstream in the future.

In terms of application scenarios, the single-motor central drive is suitable for long-distance trunk logistics where the uniform speed accounts for more than 80%, so as to simplify the transmission chain; the dual-motor central drive is suitable for uneven road conditions in mountainous areas, so as to achieve torque dynamic compensation energy saving and ensure uninterrupted power.

When running with a single motor, it is difficult to optimize the low-torque and low-efficiency landing areas; if a single-motor product needs to cover more scenario requirements, performance redundancy and the single motor’s own properties limit energy consumption optimization.

In actual applications, the dual-motor configuration operates alternately in single and dual-motor modes, effectively optimizing the low-torque and low-efficiency operating point area, which is beneficial to optimizing energy consumption in scenarios with variable vehicle speed and load. It has stronger adaptability in scenarios with frequent changes in load, speed, and road conditions. The comprehensive energy consumption of dual-motor products is 2% to 3% better than that of single-motor products.

2.2 Motor Selection for Central Drive Configurations

① Wire Type Selection: Most motors in single-motor configurations use round wire, while high-speed, low-torque motors in dual-motor configurations mostly use flat wire.

② Power and Torque: High power/high torque is the trend. Low-speed motors have a narrow high-efficiency range and poor overload capacity. They are an effective means of increasing motor power density as motor speeds increase. The combination of high-speed, low-torque dual motors offers greater power and torque, resulting in enhanced dynamics.

③ Cooling Method: Oil cooling or composite cooling is the trend. Oil coolers directly contact the stator windings, improving heat dissipation efficiency by over 30% compared to water cooling.

④ Efficiency Comparison: The optimal efficiency range for motors is typically in the medium- and high-speed ranges under high loads. However, in actual operating conditions, the most common application occurs in different speed ranges under lower loads. Therefore, a high-speed motor combined with a four-speed transmission can expand the high-efficiency range.

⑤ Application Scenarios: The high-speed, low-torque dual-motor combination offers higher efficiency in scenarios such as fully loaded hill climbing, high speeds, and frequent braking.

2.3 Central Electric Drive Transmission Gear Development Trends

In central electric drive systems, the number of transmission gears is gradually decreasing, evolving toward two and four gears. The internal configuration features a coexistence of planetary gears and parallel shafts, while system efficiency still has potential for slight improvements.

To reduce transmission weight, complexity, and cost, central drive system transmissions primarily utilize four gears. Furthermore, as motor performance improves, the number of gears may be reduced in the medium to long term.

Jiefang J6P EV: 6-speed

Fast pure electric central drive: 4/6-speed

Green Control pure electric central drive: 4/6-speed

SINOTRUK next-generation central drive: 2/4-speed

ZF Cetrax2: 3-speed

T-Baidu next-generation central drive: 4-speed

In terms of transmission, planetary gearboxes and parallel shaft configurations are in common use. Both have distinct advantages and disadvantages, and will likely coexist in transmissions for a long time.

Planetary gears:

① Compact structure and higher integration;

② High technical and manufacturing difficulty;

③Relatively low system efficiency. ZF has a technological advantage in planetary gears.

Parallel shafts:

① Simple structure, high technical maturity, and low development difficulty;

② Large system size. Domestic manufacturers primarily use parallel shaft solutions.

2.4 Central Drive System Efficiency and Cost

The dual high-speed motor central drive has advantages in weight, cost and efficiency, but it increases the difficulty in control strategy and calibration.

The overall efficiency of the central electric drive system still has room for improvement as the efficiency of electronic control and transmission improves, but it is limited.

The current central electric drive system efficiency (85-88%) = motor efficiency (92-95%) × electronic control efficiency (94-95%) × transmission efficiency (96-97%).

The efficiency of the next-generation central electric drive system (88-90%) = motor efficiency (96-97%) × electronic control efficiency (96-91%) × transmission efficiency (97-98%).

① Weight: High-speed dual motors reduce weight by over 100kg compared to a single, low-speed motor (Wanliyang).

The single-motor system weighs 500kg and outputs 23,800Nm of torque.

The dual-motor system weighs 395kg and outputs 25,600Nm of torque.

② Efficiency: The dual-motor configuration improves overall efficiency by 2% to 3%. Under low loads, a single motor drives the system, while power is distributed across the dual motors for maximum efficiency at medium and high loads, extending the high-efficiency range.

③ Cost: The powertrain system cost is reduced by over 3,000 yuan. Dual high-speed, low-torque motors reduce costs by over 5,000 yuan compared to a single, high-torque motor. Taking into account the addition of a first-stage transmission and controller, the cost reduction exceeds 3,000 yuan.

2.5 Central drive system NVH gear shaft housing design optimization

① Design and Manufacturing:

Gear Double-Sided Modification Design

Casing Modal Analysis

Dynamic Response Analysis

Gear Modification Design: Multi-objective optimization of gear parameters, including number of teeth, contact coefficient, and slip ratio, is considered.

Gear Shaft Processing: Utilizing different tolerance control processes, high-precision gear profile grinding, and high-performance dry hobbing, we achieve improved tooth profile and tooth trace micro-modification accuracy.

② Simulation and Calculation:

Gear Dynamic Meshing Force and TE Calculation

Casing Acoustic Power Radiation Simulation

Simulation and Test Correlation Comparison

② Simulation and Calculation:

Comparison of simulation and contact spot test results for consistency.

Transmission error is reduced within the speed range after optimization.

According to the waterfall chart, the optimized casing radiated SPL is reduced.

2.6 Central drive system assembly accuracy assurance – helical gear intermediate shaft gear alignment process

The dual-intermediate shaft transmission system requires power splitting, ensuring equal phase shifts between the gears on the left and right intermediate shafts. This places higher demands on the machining and assembly processes (Wanliyang):

Intermediate shaft gear hobbing and adaptive thermal post-grinding processes

Intermediate shaft subassembly gear hot-fitting processes

Gear alignment accuracy is controlled within a 50μm tolerance band.

2.7 Central Drive System Shared Oil Design and Lubrication and Cooling Calculation

①Integrated Structural Design: Integrated oil circuit structure and routing; Integrated thermal management design for cooling oil circuits

② Thermal Flow Simulation Analysis: Oil churning heat loss/heat balance testing and analysis/lubrication and cooling flow requirements/heat dissipation requirements

③ Motor-transmission integration and shared oil compatibility challenges

Excellent shaft and gear protection

Outstanding electrochemical performance

Excellent material compatibility

Outstanding heat transfer and high efficiency

2.8 Central Drive System Software Design

Dual motors, speed coupling, torque distribution, and shifting logic complicate software control. The synchronized and coordinated control of the two motors with dual electronic controls requires high standards, increasing the complexity of controller design: Accurately and timely identification of different scenarios allows for the selection of control modes based on those scenarios.

Supports optimal motor efficiency calculation under different loads.

Supports free torque distribution in dual-motor mode and torque calculation during faults or torque limits.

① Remote Flash

Supports compressed flash for faster flashing speeds.

Supports remote flashing, enabling software-defined vehicles.

Supports dual-backup operation for greater reliability.

② Functional Safety

Complies with the ISO 26262 road safety system. Overall compliance with ASILC requirements.

③ Information Security

Secure flash, secure boot, Jtag protection, P-flash protection, XCP protection, secure logging, and secure access.

2.10 Technical Challenges of Central Drive Systems

① High Speed: 12,000 rpm, 15,000 rpm, 20,000 rpm, with continuous improvement

② Multi-gear: Uninterrupted power or “perceptible” shifting technology

③ High-speed ratio transmission: Multi-stage transmission/compatibility with high speed and high load

④ Bearing selection: Selection for compatibility with high speed and high load, current resistance, and efficiency

⑤ Actuator: Highly reliable shift actuator/electric and pneumatic

⑥ Housing Integration: Integrated motor and electronic control design/rigidity

⑦ Configuration and Process: Parallel shaft/planetary gearbox, innovative configuration/manufacturing process

⑧ Ultimate Performance: High efficiency/light weight/low noise/high reliability

⑨ Cooling and Lubrication: Mechanical and electronic pump applications/oil channel design

⑩ Specialized Lubricants: Higher efficiency/better load-bearing lubrication/motor-transmission compatibility

3. Technology Development Paths for Integrated Electric Axles for New Energy Commercial Vehicles

There are four technology paths for integrated electric axles. Currently, domestic manufacturers are primarily focusing on parallel-axis electric axles with integral axles, while international manufacturers are leaning towards segmented or even coaxial electric axles.

The parallel-axis configuration with integral axles is the preferred option in the short to medium term: it offers significant improvements in space and efficiency compared to central drive and is technically feasible. In the medium to long term, segmented axles will become a key technology development point. Distributed drive, as a future technology, needs to be included in technical planning.

3.1 Commercial Vehicle Electric Drive Axle Application Conditions

① Frequent Starting and Stopping: The motor and electronic control are repeatedly loaded and unloaded in a short period of time, resulting in significant thermal shock.

② Heavy-Load Hill Climbing: The motor operates outside its high-efficiency range for a long period of time, increasing copper and iron losses.

③ Severe Vibration: Commercial vehicle electric drive axles are unsprung, and vibration acceleration can reach over 10g.

④ Extreme Ambient Temperatures: Low temperatures dramatically increase churning losses; high temperatures accelerate lubricant degradation.

3.2 E-axle Technology Development Directions

① Highly Integrated Design: Motor + Electronic Control + Transmission + Axle + TCU, etc.

② Multi-physics Coupling: Transmission (Dynamics/Ride) + Structure (Strength/NVH) + Electromagnetic Field (Control/Magnetic Circuit) + Fluid (Temperature/Lubrication)

③ Application of High-Performance Materials

④ Intelligent Control Strategies

3.3 Parallel Shaft Electric Drive Axle + Integral Axle Housing

The motor output shaft is arranged parallel to the axle half-shafts; the motor and transmission are integrated and mounted on the axle housing interface, with the axle housing remaining virtually unchanged from the era of fuel-powered vehicles.

① Integration and Efficiency: Integration is significantly improved compared to central drive, resulting in significantly higher efficiency.

② Space Utilization and Lightweight:

③ Load Capacity: The integral axle housing offers strong load capacity.

④ NVH: Unbalanced loads between the motor and reducer affect handling and comfort.

⑤ Maintainability: The motor and transmission are easily disassembled, resulting in low maintenance costs.

⑥ Technical Feasibility: The design is easily implemented with minimal changes to the traditional axle configuration.

Typical Products: FAW Jiefang Electric Drive Axle, Sinotruk Electric Drive Axle, etc.

3.4 Parallel-Shaft Electric Drive Axle + Segmented Axle Housing

The motor output shaft is arranged parallel to the axle half-axles; the original integral axle housing is divided into left and right sections, with the motor and transmission housing serving as the center section. This is also known as a three-section axle housing.

① Integration and Efficiency: Integration and efficiency are significantly improved compared to central drive systems.

② Space Utilization and Lightweighting:

③ The axle housing is a three-section structure connected by bolts, resulting in a complex structure and increased weight, but the load-bearing capacity meets highway load requirements.

④ NVH: Unbalanced load issues are improved compared to parallel axle systems.

⑤ Repairability: Repairs require disassembling the axle housing and motor/transmission.

⑥ Technical Feasibility: The motor and transmission are designed as a complete, completely new unit, requiring significant effort and difficulty.

Typical products: Fiat Powertrain, Huayong electric drive axles, etc.

3.5 Coaxial Electric Drive Axle

The motor and drive axle are deeply integrated, sharing a common output shaft.

① Integration and Efficiency: The transmission structure is more streamlined, but the use of planetary gearboxes is somewhat less efficient than parallel shaft gearboxes.

② Space Utilization and Lightweight: Deep integration reduces components, resulting in a more compact and lightweight design, taking up less space.

③ Load Capacity: The axle housing is a three-section structure connected by bolts, resulting in a complex structure and increased weight. Compared to a three-section parallel shaft structure, the moment-bearing cross-section is smaller. Through optimized design, the load capacity can meet highway load requirements.

④ NVH: There is virtually no load eccentricity, resulting in the best NVH performance.

⑤ Maintainability: High integration reduces maintainability.

⑥ Technical Feasibility: A completely new design is required, and the design and manufacturing process of the planetary gearbox are relatively complex.

Typical products include the ZF coaxial electric drive axle.

3.6 Vertical-Axis Electric Drive Axle

The motor output shaft is arranged perpendicular to the drive axle axis; the motor and transmission are integrated and assembled on the axle housing interface. The axle housing and fuel-powered vehicles remain virtually unchanged.

① Integration and Efficiency: Due to the presence of spiral bevel gears, NVH (Non-Volatile Harshness) during reverse braking affects brake energy recovery, impacting overall energy efficiency.

② Space Utilization and Lightweight: Slightly better than central drive, but weaker than parallel-axis electric drive axles.

③ Load Capacity: The integral axle housing provides greater load capacity.

④ NVH: The longer cantilever length makes it more susceptible to deflection.

⑤ Maintainability: The motor and transmission can be repaired separately.

⑥ Technical Availability: The original product requires minimal changes, but the reverse torque of the spiral bevel gears is difficult to resolve.

Typical products include Meritor vertical-axis electric drive axles.

4. Electric Axle Thermal Management

4.1 Requirements for Integrated Thermal Management of Electric Axles

The trend in electric axle integration: From discrete modular systems such as the motor, electronic control, reducer, and axle to an all-in-one integrated electric axle.

Building an integrated electric axle thermal management system:

1) Multiple discrete cooling systems are complex and limited in efficiency. Multiple cooling media are used. Components are redundant and have redundant performance. Long heat transfer paths limit heat exchange efficiency.

2) Discrete thermal management systems struggle to meet thermal management requirements in low-temperature conditions. Insufficient waste heat supply and high cost of multi-scenario applications. Low-temperature requirements include: power, battery heating, PTC heating, and membrane heating.

Integrated solution: Power (motor drive) + battery heating.

①Waste Heat Utilization: Recovering waste heat from the electric drive to feed the heat pump and reduce energy consumption.

②Active Heat Generation: Controlling inefficient electric drive operation to generate large amounts of heat.

Deeply integrated topology design: Integrated drive, charging, and heating functions.

① Solution Principle: Reusing the MCU drive circuit to synchronously control the three-phase duty cycle and inductive oscillation pulse heating.

② Reusing the MCU circuit: Different frequencies and currents can meet different battery temperature rise rates.

4.2 Integrated thermal management technology for electric drive axles

1) Separate thermal management of batteries and electric drive axles

① Multiple cooling media, long heat exchange paths, and complex piping

② Thermal shock can easily cause localized high temperatures, making it difficult for independent systems to respond promptly

③ Low-temperature heat pumps have limited heating capacity, and waste heat from motor and electronic controls is difficult to utilize.

2) Integrated thermal management system

① Composite cooling technology

Reduces the amount of coolant added to the thermal management system.

Shortens the heat exchange path and improves heat exchange efficiency.

Integrated thermal management, combined with intelligent pulse self-heating technology, achieves complementary cooling and heating

② Direct cooling of refrigerant in the electric drive axle

Exploiting the high COP advantage of direct cooling to reduce energy consumption in the thermal management system.

Using direct cooling of refrigerant to improve the heat transfer coefficient and achieve rapid response of thermal management.

Simplifies the system, reduces the number of components and coolant quality, and reduces maintenance costs.

4.3 Design of an Efficient Thermal Management System for an Electric Axle

1) Highly Integrated Cooling Structure Design

① Shared oil and housing for the motor and reducer.

② Integrated active lubrication design for the motor and reducer.

③ Dual oil circuits for stator and rotor cooling.

④ Intelligent control of stator and rotor oil circuit zones (reducing the maximum rotor temperature rise by 50°C).

2) Highly Efficient Active Lubrication for Multiple Operating Conditions

① Adjusting the lubrication circuit based on the operating conditions of the electric axle to improve system heat exchange efficiency.

② Reducing oil pump operating power loss to adapt to various environmental conditions.

③ Development of active lubrication strategies.

3) Development and Application of High-Performance Lubricants

① Improving oil performance and production cleanliness to achieve maintenance-free and extended oil change intervals.

② Applying low-viscosity oils to improve electric axle efficiency and low-temperature performance.

③ Improving oil compatibility while ensuring oil load capacity to achieve shared oil for the motor and reducer.

4) Highly Efficient, Low-Churning-Loss Lubrication Design

① Oil baffle mechanism and high-speed, low-churn design: High-speed oil storage and baffle structures reduce churn losses by 200W.

② Highly Efficient Active Lubrication Design: Multi-circuit active lubrication, adjusting the lubrication circuit based on oil temperature to accommodate various environmental conditions.

4.4 Thermal management performance verification of electric drive axle

1) Simulation verification technology

① One-dimensional simulation of lubrication system: lubrication system architecture design, nozzle diameter optimization, oil pump and solenoid valve strategy simulation

② Flow distribution simulation: detailed flow and pressure simulation of each oil circuit, temperature rise simulation of lubrication point

③ Motor oil throwing and gear oil stirring simulation: oil stirring-oil throwing loss simulation, oil return condition simulation, oil filling amount and oil pumping verification

2) Key performance test verification

① Oil pump performance calibration test: low temperature starting ability test, oil pump performance test

② Heat transfer performance calibration test: heat transfer capacity test, flow resistance test

③ Assembly oil circuit simulation performance calibration test: assembly oil circuit flow resistance characteristic test, providing conditions for component testing

④ Window/transparent shell lubrication test: oil distribution of electric drive axle system, key point lubrication evaluation, system temperature rise test, resistance test

3) Temperature prediction model

Power device junction temperature prediction model, motor thermal resistance network

4.5 Summary of E-axle Thermal Management

1) To meet market and customer demands, high reliability, high integration, high performance, and intelligence will remain the core of commercial vehicle e-axle and thermal management system development in the long term.

2) Coupling multi-physics fields and applying high-performance materials to achieve high integration of e-axle thermal management systems will be key areas of future technological development.

3) Predicting e-axle operating conditions based on real-time road data and implementing intelligent control of the thermal management system will further enhance the system’s performance.

A00 passenger car motors use natural cooling (radiation/evaporation), while commercial vehicles, with their higher power, all use forced cooling. Forced air cooling (built-in/external fans) is only used in A0-class cars. New energy commercial vehicles generally use forced liquid cooling (water/oil):

① Overall liquid cooling: indirect/direct/hybrid cooling

② Local liquid cooling: generally for cast aluminum asynchronous motors

5.1 Water-Cooled Motors

Using coolant as the cooling medium, the main heat transfer path within the motor is: windings – insulation layer – stator core – housing – coolant.

① Advantages: Low cost, simple structure, mature and reliable technology

② Disadvantages: Long heat transfer path, heat transfer efficiency significantly affected by assembly thermal resistance

Motor water channel types:

① Axial: High heat transfer efficiency but high flow resistance

② Circumferential: High heat transfer efficiency but high flow resistance

③ Spiral: Low heat transfer efficiency but low flow resistance

5.2 Oil-Cooled Motors

Using cooling oil to directly cool the windings, core, and magnets shortens the heat transfer path and can meet high-load heat dissipation requirements. This is a major future development trend for electric drive axles.

① Advantages:

Direct cooling of heat-generating components, high heat dissipation efficiency

High system integration (integrated motor/reducer design)

② Disadvantages:

Complex oil circuit structure, requiring high oil quality

Risk of localized overheating

Oil Cooling Methods:

① Winding oil immersion cooling

② Rotor oil spraying + winding oil spray cooling

5.3 Motor Zoned Thermal Management Technology

1) Problems with the Existing Technology:

① Water-cooled motors are prone to overheating in complex operating conditions.

② High oil throw-off losses in the rotor oil circuit reduce motor efficiency.

2) Stator and rotor zoned and rotor bidirectional cross-cooling technology solutions:

① Dual-path oil cooling for stator and rotor

② Zoned stator and rotor oil circuit design

5.4 Reducing Internal Thermal Resistance of the Motor

① Use hair-pin windings to increase slot fill rate

② Improve slot filling efficiency with insulating varnish

③ Increase the thermal conductivity of the insulating material (high thermal conductivity impregnation varnish/high thermal conductivity nano-insulating paper)

④ Fill the gap between the winding end and the housing with thermally conductive insulating material

⑤ Improve the fit between the housing and the motor body, increasing the interference fit

⑥ Use oil cooling or direct oil cooling to shorten the heat transfer path

⑦ Increase the heat dissipation surface or flow rate (design a wave channel/use heat dissipation pins/add heat dissipation ribs, etc.)

6 Electronic Control Thermal Management Technology

Meets the heat dissipation requirements of electronic control systems in high-power, compact designs.

6.1 Power Module Thermal Management

① Indirect liquid cooling: Flat heat sink, thermal grease, indirect contact

② Direct liquid cooling: Pin-type heat sink, no thermal grease, direct contact

③ Double-sided liquid cooling: Pin-type heat sink, no thermal grease, double-sided direct contact

BYD’s power module thermal management utilizes a pin-fin direct liquid cooling solution, replacing an indirect liquid cooling solution, and employs a laminated laser welding process instead of bolted connections. Advantages:

① The power module’s heating surface is in direct contact with the coolant, resulting in a large heat exchange area and high heat transfer efficiency.

② Lower thermal resistance, helping to reduce the power module’s junction temperature.

③ Rapid response to power module temperature changes.

6.2 Capacitor Thermal Management

① Natural Cooling: Customized plastic housing, natural cooling, for low-power applications.

② Metal Base Plate Cooling: Customized plastic housing, metal base plate, for higher-power applications.

③ Direct Liquid Cooling: Multi-faceted metal housing, direct cooling, for high-power applications.

BYD’s capacitors feature internal three-dimensional water channels, shared with the power module, allowing the capacitors to directly contact the coolant. Advantages:

① Contact heat transfer through the coolant significantly improves heat dissipation efficiency and further reduces capacitor hotspot temperatures.

② Supports a three-dimensional fit with the capacitor body, with cooling channels embedded within the capacitor housing, improving space utilization.

7 Commercial Vehicle Wheel Hub Motors

7.1 In-Wheel Motor Drive Configurations

① Direct Drive: A low-speed, high-torque external rotor motor with a peak speed of 1000-1500 rpm and no reduction mechanism. The system achieves a maximum efficiency of 90-95%. The motor rotor is directly and rigidly connected to the wheel hub, resulting in a low system torque density.

② Reduced Drive: An internal rotor high-speed motor with a peak speed of 10,000-15,000 rpm is used with a reduction mechanism, typically a planetary gearbox. The efficiency is generally 88-94%. This reduction drive solution offers advantages in terms of size, weight, and cost, but is slightly less efficient.

7.2 Advantages and Disadvantages of In-Wheel Motors and Market Application

Compared to other commercial vehicle configurations, hub motors offer advantages such as high integration, small footprint, and a short power transmission path. Furthermore, an electronic differential can improve vehicle handling. However, due to limitations in the mounting layout, system sealing, heat dissipation, and vehicle ride comfort present significant challenges.

In the commercial vehicle sector, in-wheel motors are primarily used in mining trucks weighing over 100 tons. Conventional trucks primarily rely on central drive and integrated electric axles for new energy propulsion. In-wheel motors have yet to achieve mass production in engineering applications.

7.3 Technical Difficulties of In-Wheel Motors

① In-wheel space constraints lead to low efficiency: The axial and radial dimensions of in-wheel hub motors are limited by the space inside the wheel hub. Consequently, they often utilize fractional-slot centralized windings and surface-mount/straight-line embedded permanent magnet motor designs. These motors have a high number of poles, high frequency, and high iron loss. This is especially true for outer rotor designs, where the increased number of poles significantly impacts motor efficiency. Currently, the industry’s highest efficiency for in-wheel hub motors is approximately 95%, lower than conventional drive motors (currently reaching a maximum efficiency of 98%). Furthermore, due to space constraints within the wheel hub, improving efficiency is difficult.

② Poor heat dissipation and motor demagnetization: In-wheel hub motors are fully integrated within the wheel rim, resulting in a short heat dissipation path and a poor heat dissipation environment. Heat generated during motor operation is difficult to dissipate, especially during braking on long downhill slopes and under full power conditions. The combined braking heat and motor heating can easily lead to uncontrolled temperature rise, increasing the risk of demagnetization of the motor’s permanent magnets.

③ Poor operating environment and great difficulty in sealing: The hub motor is installed inside the wheel, which is lower than the central drive motor and has harsher working conditions. It is at greater risk of damage from ground impact, sand, mud and water pollution. In particular, the reduction drive solution is difficult to seal (oil, water, gas in multiple dimensions, large-diameter oil seals have high linear speeds), and coupled with the difficulty in heat dissipation, the risk of oil seal failure is even greater.

Hybrid heavy-duty trucks were first researched by major European truck companies, including Daimler. The hybridization approach involved converting from PO to 48V to P2. However, the P0 hybrid ratio was very low, and there was a correlation between the hybrid ratio and fuel efficiency, resulting in poor fuel efficiency. While the hybrid ratio improved in the P2 stage, fuel efficiency still fell short of customer demand.

Great Wall pioneered the third stage using series-parallel technology, improving comfort, power, and economy. The high hybrid ratio allows for a variety of complex driving conditions. The dual electric motors provide power compensation during shifts, ensuring smooth shifting.

Great Wall’s heavy-duty truck hybrid architecture utilizes a series-parallel configuration and is named Hi4-G.

Great Wall’s 8-speed DHT hybrid-specific transmission, paired with a 360kW motor, is the industry’s first heavy-duty truck transmission with shared oil cooling and lubrication for both the transmission and motor. The hybrid DHT utilizes multiple intermediate shaft technology, achieving the industry’s highest torque of 4,500 Nm for heavy-duty truck transmissions. Furthermore, an oil-cooled co-lubrication system has been developed for the Hair-pin flat-wire motor, integrating the cooling and lubrication circuits of the transmission and motor to reduce overall structural complexity.

The Hi4-G boasts a 24% improvement in power compared to the P2 configuration. Under the CHTC-TT operating conditions, including mountain roads in Yunnan and Guizhou, the Hi4-G achieves a 4.5% to 7.9% improvement in fuel efficiency compared to the P2. Great Wall’s 8-speed DHT heavy-duty trucks feature 10 operating modes, intelligently selecting the most economical mode for each application:

① Based on the scenario, pure electric power is used for starting, eliminating fuel consumption during startup. Extended-range mode is used at low speeds, including in traffic jams. Once on the main road, a single motor assists acceleration, further saving fuel.

② For low-speed highway driving, a hybrid mode is available. At high and medium speeds, direct drive is used when the engine reaches its high-efficiency zone for maximum fuel efficiency. Parallel mode is used for overtaking and climbing, with dual motor assistance ensuring safe and efficient overtaking.

③ For braking safety, both single and dual motors ensure smooth downhill driving over long periods of time. Furthermore, the vehicle can generate electricity while parked, meeting various daily needs.

④ In pure electric mode, the Hi4-G efficiently adjusts the dual motors, ensuring both operate within their high-efficiency range.

⑤ In high-speed climbing mode, the parallel drive mode allows the Hi4-G to adjust the engine and two motors to their optimal operating points, increasing overall efficiency by 7% and fuel savings by 14.6% to 16.2%.

9.1 Advantages of Trailer Electric Axles

① Energy Saving and Consumption Reduction: Energy recovery during braking reduces fuel consumption and improves driving range.

② Assisted Driving: Assists driving under adverse conditions, such as providing power support when climbing hills, increasing traction when starting on slippery roads, and escaping mud pits.

③ Power Output: Powers auxiliary equipment requiring power, such as the refrigeration system of refrigerated trucks.

④ Braking Safety: Improves braking performance and driving safety on long downhill slopes.

9.2 Disadvantages of Electric Trailer Axles

① Increased costs: Additional components such as batteries, motors, and electronic controls are required.

② Increased weight: The increased number of components increases the trailer’s deadweight, impacting operational load capacity.

③ Technical difficulties: Issues exist regarding vehicle-trailer matching and control, as well as information transmission stability.

9.3 Industry Layout

① KRONE: Has launched the eCoolLiner electric refrigerated trailer, equipped with an 800V high-voltage platform, an electric drive axle, and a fast-charging system, which can reduce fuel consumption by up to 40%.

② ZF: In 2023, it will release the new eTrailer electric trailer, integrating the modular Axtrax2 electric drive axle and battery system, which can reduce fuel consumption by up to 16%.

③ Gong Xiang: The electric trailer will roll off the production line in 2023. It will have a 160kW motor and a 40kWh battery capacity, enabling a range of 40km and fuel savings of 15-20%.

9.4 Summary

① Due to disadvantages in cost and weight, and the lack of clear regulations in China, large-scale adoption has been slow.

② True trailers are highly applicable and have significant advantages in scenarios requiring electricity (such as refrigerated trucks) and mountainous terrain, and are expected to penetrate the market first.

10 Typical Electric Drive Products for New Energy Commercial Vehicles

10.1 Wanliyang Single-Motor Four-Speed Central Electric Drive

Rated power 330kW, peak power 450kW.

Rated input torque 1800Nm, maximum input torque 2800Nm.

Rated speed 2000rpm, peak speed 3500rpm.

Transmission gear ratios: 8.51, 3.88, 1.88, 1.00.

Dimensions 1135×530×581.

Weight 500kg (motor 290kg + transmission 180kg + controller 30kg).

10.2 Wanliyang Dual-Motor Four-Speed Central Electric Drive

Rated power 180kW x 2, peak power 250kW x 2.

Rated input torque 300Nm x 2, maximum input torque 500Nm x 2.

Rated speed 6300rpm, peak speed 10,000rpm. Transmission gear ratios: 25.614, 12.792, 6.250, 2.966.

Dimensions: 1190 × 590 × 500.

Weight: 395kg (motor 135kg + transmission 230kg + controller 30kg).

10.3 Disc Hub Heavy-Duty Truck Electric Drive Axle

Disc Hub High-Efficiency Axial Flux Motor Axle:

① Axle Load: 11.5T/13T

② Applicable Vehicle Types: 25T/31T/49T

③ Leaf Spring Installation Distance: 970-1040mm

④ Speed Ratio (3AMT + Wheel-End Planetary Gear): (13.58/5.48/2.63) x 3.947

⑤ Motor Platform:

295 Stator Outer Diameter: Motor Rated Power 140kW/Motor Peak Power 220kW/Wheel-End Peak Torque 3754N 2Nm

315 stator outer diameter: motor rated power 165kW/motor peak power 230kW/wheel peak torque 48,268Nm

335 stator outer diameter: motor rated power 200kW/motor peak power 300kW/wheel peak torque 56,000Nm

⑥ Controller: 600A/800A

⑦ Full-load ground clearance: ≥285mm

Actual installation and operation: Already in mass production for Shaanxi Automobile heavy-duty trucks, cumulative delivery of over 4,000 units is expected by 2025.

10.4 Daimler eActros 600 Electric Drive Axle

① Utilizing the oil-to-electric platform, the electric drive axle adopts a one-piece axle housing with parallel shafts and a dual-motor design for improved efficiency.

② Dual motors + 4-speed transmission, total rated power 400kW, peak power 600kW.

③ Jointly developed with Bosch for commercial vehicle motors, sharing the passenger vehicle motor production line. ④The dual-motor design makes it easier to distribute power and improve system efficiency.

10.5 Tesla Semi Electric Drive Axle

The Tesla Semi’s all-electric heavy-duty truck utilizes a dual-axle, three-motor electric drive axle. The first rear axle features a single motor in single gear, while the second rear axle features dual motors in two gears with a power disconnect device. Both are equipped with inverters. Deliveries will begin at the end of 2022, with a total of 600 units delivered to date.

Power Delivery Strategy: The dual electric drive axles must be used in conjunction.

During the start-up and climb phase: The second rear axle clutch engages, power is delivered, and the dual motors, with their high power, quickly reach the economic cruising speed.

High-speed cruising: Once the economic cruising speed is reached, the second rear axle clutch disengages, cutting power, and the first rear axle motor independently drives the vehicle within its optimal efficiency range.

Matching Power Demand to Motor Efficiency Zone: Based on operating conditions and power requirements, an intelligent, electronically controlled torque clutch adjusts the motor power combination to ensure operation within the high-efficiency range, reducing power consumption. During highway cruising, only the first rear axle motor is used, with the second rear axle power decoupled. The single-speed reducer on the first rear axle: Based on high-performance motor and electronic control technology, it utilizes a single-speed reducer similar to that used in passenger cars to further reduce transmission losses and shorten development cycles.

Power: Under extreme operating conditions, up to three motors rated at 360kW can achieve combined power output.

Major quality issues encountered during Tesla’s electric axle operation include motor overheating due to oil pump stalling, motor erosion/insulation degradation, oil seal leakage, bearing electrical corrosion, and MCU communication interruption.

Tesla’s heavy-duty truck electric axle development plan includes a segmented parallel-axis electric axle (2028) and a coaxial electric axle (after 2030).